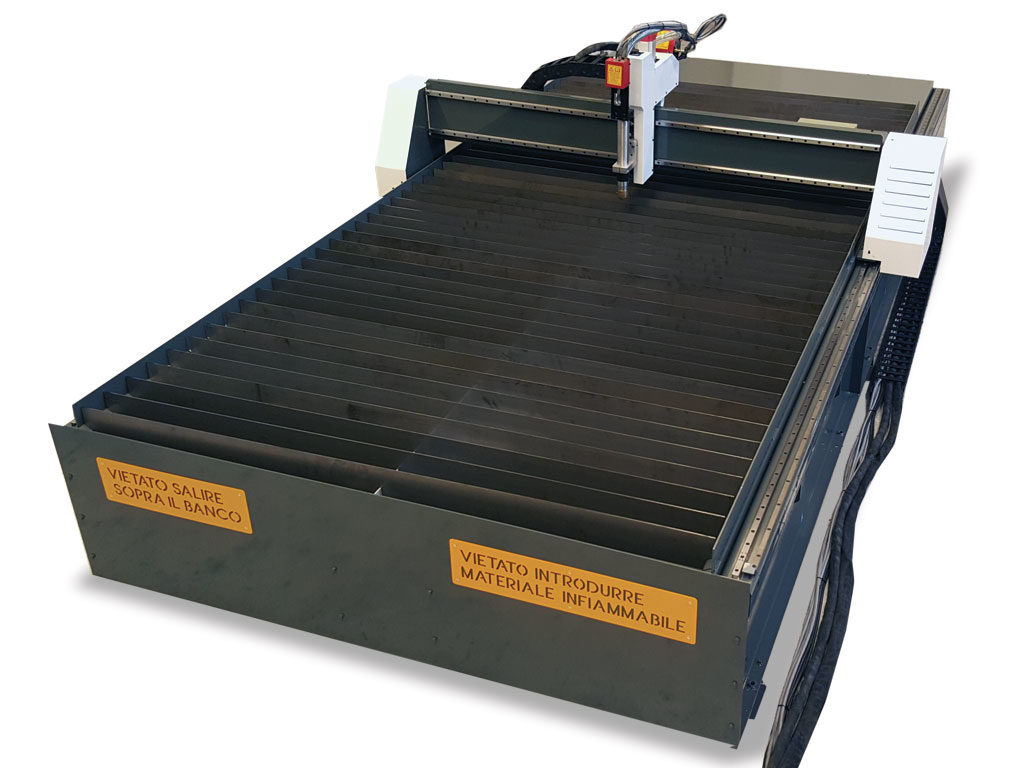

AMC SYSTEM PLASMA CUT

Technical Features:

- Work space: 1500 x 3000 mm / 2000 x 4000 mm / 2000 X 6000 mm

- Automatic torch height control

- Max acceleration: 1.5 m / s2

- Maximum interpolated speed: 40 m / min

- Machine electrical power: 1.5 kW

- Z axis travel: 200 mm

SUCTION BENCH

Designed to support sheets of materials such as: steel, aluminum, stainless steel, iron up to 40 mm thick, divided into modular sectors (approx. 750 mm) each equipped with an electro-pneumatic opening and closing system to allow localized aspiration at the time of cutting for better efficiency.

HANDLING

Linear guides with recirculating balls to guarantee superior performances.

Double motorization with Brushless motors equipped with self-aligning system and clearance recovery for greater reliability, balance and precision. Motion transmission via pinion and rack to ensure greater transmission and consequently better efficiency. Unmatched precision and performance.

SOFTWARE

Industrial hardware to be able to withstand any operating stress condition. Software with user-friendly interface for easier interaction between operator and machine.

Internal CAD with the possibility of optimizing the scrap of the sheet on the machine, complete with parametric figures with the possibility of importing DXF files without going through external CAD / CAM. Remote assistance for rapid assistance and direct interventions online. External CAD for better management of scraps and cutting optimization.

Technical Features:

- Work space: 1500 x 3000 mm / 2000 x 4000 mm / 2000 X 6000 mm

- Automatic torch height control

- Acceleration max: 3 m/s2

- Maximum interpolated speed: 65 m/min

- Machine electrical power: 3 kW

- Z axis stroke: 160 mm

- Reduced size

- Monobloc bench for a better kinematic

- Easy of installation and use

EASYCUT

ASPIRING BENCH

Expected to support sheet materials such as: steel, aluminum, stainless steel, mild steel up to 100 mm thickness, divided into modular sections (700 mm approx) each equipped with an opening and closing system electropneumatic to allow the suction localized at the time of cutting for better optimization of the suction power.

HANDLING

Head plasma and movements on linear guides with recirculating ball movement through pinions and tilted racks for extra grip / precision. Brushless motors with low backlash gearbox for the superior performance that can reduce downtime between one cut and the next.

SOFTWARE

Control with touch-screen panel features a Cad inside with 60 parametric figures for fast nesting without having to move from workstation equipped with CAD / CAM software outside. Predisposition for remote assistance to provide the customer with a ready help in cases of doubt / problems.

EASYCUT

Control with touch-screen panel features a Cad inside with 60 parametric figures for fast nesting without having to move from workstation equipped with CAD / CAM software outside. Predisposition for remote assistance to provide the customer with a ready help in cases of doubt / problems.

Technical Features:

- Designed for large cutters

- Automatic torch height control

- max acceleration: 3 m / s2

- Maximum interpolated speed: 65 m / min

- Machine electrical power: 3 kW

- Travel Z-axis: 240 mm

- separate bench by the crossbar to facilitate loading / unloading of sheets

- Possibility of installing oxyfuel / head bevel / drilling unit

ASPIRING BENCH

Expected to support sheet materials such as steel, aluminum, stainless steel, mild steel up to 100 mm thick (Capability to support higher thickness on request), divided into modular sections (700 mm approx) each equipped with an electro-pneumatic system opening and closing to allow for the localized extraction at the time of the cut for a best efficiency.

HANDLING

Linear Guides Ball to enable superior performance. Twin motors with self-alignment system for increased reliability. Left floating for recovering the mechanical backlash. motion transmission via rack and pinion with helical teeth to ensure better grip and consequently a better yield. aluminum engine mounts for improved vibration resistance.

SOFTWARE

Industrial PC to be able to resist any situation. Software with user-friendly interface for ease of interaction between operator and machine. CAD interior with possibility of nesting on board 60 figures paramatrich more the possibility to import DXF files without having to CAD / CAM external. Teleservice for quick assistance or just any doubts.

OPTION AVAILABLE

- ISO drilling unit 30 with 6 tools and automatic transmission

- Unità di lubrificazione minimale

- Possibilità di montaggio moltiplicatore di coppia

- Cannello ossitaglio completo di valvole proporzionali e capacità di taglio fino a spessori di 300 mm

- Controllo durante il taglio con sistema capacitivo

- Accensione automatica

- 3D plasma bevel cutting head for infinite rotation and tilt angle +/- 47 °

- Dot peen marking unit and inkjetSupercut

S1 can be interfaced with any type of plasma generator currently existing on the market.